Which gap should you identify?

##BeginCaseStudy###

Case Study# 1

Corporate Information and Physical Locations

Woodgrove Bank is a national financial services institution that operates in over 30 cities across

the United States. The company offers investment banking services, has over 140,000

employees, and has five departments.

EXISTING ENVIRONMENT

Existing Business Processes

Woodgrove Bank has the strategic goal of eliminating 25 percent of its current list of 40,000

suppliers. The bank has begun eliminating suppliers based on their prices, redundant product or

service offerings, and past supplier performance. The company’s Enterprise Supplier

Management (ESM) group manages the supplier elimination process. The group also directly

manages the bank’s largest suppliers and provides training material and workshops on supplier

management to the company departments.

The Woodgrove Bank ESM group has the following business processes:

The ESM group collects supplier performance data for the 2,000 largest suppliers.

The ESM group’s Supplier Managers use supplier performance data to directly manage the 40

largest suppliers.

The department managers directly manage all other suppliers.

The ESM group provides performance data on other suppliers to the department managers by

request. Raw performance data is organized in spreadsheets that are sent via e-mail.

The ESM group’s Business Analysts collect and store supplier performance data in multiple

spreadsheets. The spreadsheets are stored on the Analysts’ local computers and contain many

different types of supplier performance metrics. Each quarter, the ESM group surverys the

department managers to discover the level of satisfaction they have for each of their suppliers.

Business Analysts distribute the surveys via e-mail then manually consolidate the survey results.

Existing Technology Infrastructure

Woodgrove Bank has the following software deployed on all desktop computers:

Microsoft Office 2003 Professional

Windows XP Professional

Woodgrove Bank has the following software deployed on all network servers:

Windows Server 2008

Windows SharePoint Services 3.0

Microsoft SQL Server 2008

Microsoft Office Project Server

The Woodgrove Bank ESM group has the following technology infrastructure:

A single IT Specialist who has minimal database application development experience.

Additional servers available for the deployment of new technology solutions.

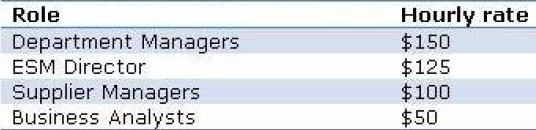

Labor Costs

The following table illustrates labor costs for salaried stall.

BUSINESS REQUIREMENTS

Problem Statements

Woodgrove Bank has identified the following business problems:

The process of manually entering data for suppliers in spreadsheets is time-consuming for the

business analysts.

Supplier data is stored in multiple files, formats, and locations.

There is very little sharing of valuable supplier performance data outside of the ESM group.

The ESM group has a fixed number of employees and very limited budget.

Business Goals

Bank executives formed the ESM group to promote best practices in supplier management

throughout the entire company.

The ESM group has the following business goals:

Build a new Supplier Performance Data Management service to distribute supplier performance

informantion across all departments.

Provide documentation to show departments how to best use company-wide supplier

performance information when negotiating individually with suppliers.

Minimize ESM group operating expenses by eliminating the procurement of additional software

licenses.

INTERVIEWEES

ESM Director

The ESM Director is a business decision maker who manages the day-to-day operations of the

ESM group.

The ESM Director best understands how the ESM group fits within the bank’s corporate strategy.

Supplier Managers

The Supplier Manager is a role within the ESM group.

Supplier Managers manage the 40 largest suppliers.

Supplier Managers best understand how supplier performance data is used to manage suppliers.

Business Analysts

Business Analysts collect and store supplier performance data.

Business Analysts query the distributed spreadsheets by request from the Supplier Managers.

Business Analysts provide insight into manual data managemt processes.

Department Managers

Department Mangers are responsible for managing their respective supplier relationships.

Department Managers provide insight into how supplier performance data is used for supplier

management at the dapartment level.

You are evaluating a Microsoft Office PerformancePoint Server 2007 solution for Woodgrove

Bank. You need to identify the gap that exists between the banks current state and its future state

based on the maturity level of the current infrastructure. Which gap should you identify?

Which issue should you choose?

##BeginCaseStudy###

Case Study# 1

Corporate Information and Physical Locations

Woodgrove Bank is a national financial services institution that operates in over 30 cities across

the United States. The company offers investment banking services, has over 140,000

employees, and has five departments.

EXISTING ENVIRONMENT

Existing Business Processes

Woodgrove Bank has the strategic goal of eliminating 25 percent of its current list of 40,000

suppliers. The bank has begun eliminating suppliers based on their prices, redundant product or

service offerings, and past supplier performance. The company’s Enterprise Supplier

Management (ESM) group manages the supplier elimination process. The group also directly

manages the bank’s largest suppliers and provides training material and workshops on supplier

management to the company departments.

The Woodgrove Bank ESM group has the following business processes:

The ESM group collects supplier performance data for the 2,000 largest suppliers.

The ESM group’s Supplier Managers use supplier performance data to directly manage the 40

largest suppliers.

The department managers directly manage all other suppliers.

The ESM group provides performance data on other suppliers to the department managers by

request. Raw performance data is organized in spreadsheets that are sent via e-mail.

The ESM group’s Business Analysts collect and store supplier performance data in multiple

spreadsheets. The spreadsheets are stored on the Analysts’ local computers and contain many

different types of supplier performance metrics. Each quarter, the ESM group surverys the

department managers to discover the level of satisfaction they have for each of their suppliers.

Business Analysts distribute the surveys via e-mail then manually consolidate the survey results.

Existing Technology Infrastructure

Woodgrove Bank has the following software deployed on all desktop computers:

Microsoft Office 2003 Professional

Windows XP Professional

Woodgrove Bank has the following software deployed on all network servers:

Windows Server 2008

Windows SharePoint Services 3.0

Microsoft SQL Server 2008

Microsoft Office Project Server

The Woodgrove Bank ESM group has the following technology infrastructure:

A single IT Specialist who has minimal database application development experience.

Additional servers available for the deployment of new technology solutions.

Labor Costs

The following table illustrates labor costs for salaried stall.

BUSINESS REQUIREMENTS

Problem Statements

Woodgrove Bank has identified the following business problems:

The process of manually entering data for suppliers in spreadsheets is time-consuming for the

business analysts.

Supplier data is stored in multiple files, formats, and locations.

There is very little sharing of valuable supplier performance data outside of the ESM group.

The ESM group has a fixed number of employees and very limited budget.

Business Goals

Bank executives formed the ESM group to promote best practices in supplier management

throughout the entire company.

The ESM group has the following business goals:

Build a new Supplier Performance Data Management service to distribute supplier performance

informantion across all departments.

Provide documentation to show departments how to best use company-wide supplier

performance information when negotiating individually with suppliers.

Minimize ESM group operating expenses by eliminating the procurement of additional software

licenses.

INTERVIEWEES

ESM Director

The ESM Director is a business decision maker who manages the day-to-day operations of the

ESM group.

The ESM Director best understands how the ESM group fits within the bank’s corporate strategy.

Supplier Managers

The Supplier Manager is a role within the ESM group.

Supplier Managers manage the 40 largest suppliers.

Supplier Managers best understand how supplier performance data is used to manage suppliers.

Business Analysts

Business Analysts collect and store supplier performance data.

Business Analysts query the distributed spreadsheets by request from the Supplier Managers.

Business Analysts provide insight into manual data managemt processes.

Department Managers

Department Mangers are responsible for managing their respective supplier relationships.

Department Managers provide insight into how supplier performance data is used for supplier

management at the dapartment level.

You need to document which key technology infrastructure issues prevent the ESM group from

meeting its goals. Which issue should you choose?

Which financial benefit should you identify?

###BeginCaseStudy###

Case Study# 2

Corporate Information and Physical Locations.

Fabrikrm,Inc. is a building materials manufacturing company that specializes in producing raw

materials. Fabrikam customers include companies that make products for residential and

commiercial construction projects. Fabrikam has 5,000 employees and earns $600 million in

annual revenues. Fabrikam has plans and offices worldwide.

EXISTING ENVIRONMENT

Existing Business Processes

Fabrikam has the following business processes:

The Plant Safety department is responsible for notifying and scheduling employees for safety

training and medical testing procedures. The department also records and reports on training and

testing procedures for management and government safety regulatory agencies. All emplloyees

are required to pass an annual mine safety training course and various medica certification tests

to continue working. Non-compliant employees cannot work, reducing production enfficiency.

Government safety inpectors perform random onsite inspections and verify that employees are

certified. Each item of non-compliance costs Fabrikam time and lowers employee productivity.

The Plant Safet department hired a full-time Safety Coordinatinator and a temporary employee to

help employees maintain their certifications. They notify employees when their certifications are

about to expire and assist employees to schedule appointments to renew their certifications.

Existing Technology Infrastructure

Fabrikam has the following technologies implemented on the network:

A third-party, Web-based workforce management application

A Microsoft SQL Server-based Enterprise Resource Planning (ERP) system

Microsoft Office Excel used to update safety information by using spreadsheets.

Farbrikam has a Microsoft Enterprise Agreement (EA) that includes Microsoft Software

Assurance (SA). All client computers run either Microsoft Office Standard Edition 2003 or

Microsoft Office 97. The department is underskilled and understaffed.

BUSINESS REQUIREMENTS

Planned Changes

Fabrikam has the following business goals:

Provide role-based access to process, operational, and financial information.

Eliminate paper-based processes, including reporting processes.

Reduce the number of technology platforms that require support.

Problem Statements

Fabrikam has identified the following business problems:

Mine safety compliance issues have shut down production at some plants, creating 60 days of

lost productivity during the past year.

Safety training records are often inaccessible.

Training dates and medical testing results are often outdated.

Safety reports are only available to managers at the end of each month.

Safety performance metrics are shared via e-mail only.

Plant safety training and medical testing data is recorded on paper forms and then entered

manually into a spreadsheet on a Safety Manager’s computer.

Reporting is delayed because safety data is outdated and inaccurate.

Business Goals

Fabrikam has the following business goals:

Reduce costs associated with meeting regulatory compliance requirements:

Eliminate paper-based processes.

Improve access to safety performance reporting.

INTERVIEWEES

Vice President (VP) The VP is the executive responsible for overseeing general business

operations and for maintaining profitability. VP goals include:

Rducing operational cost. Increasing production productivity

Eliminating plant shutdowns caused by non-compliance.

Plant General Manager

The Plant General Manager (GM) is responsible for maintaining plant profitability, operational

efficientcy, production costs, product quality, and employee safety. Plant GM goals include:

Automating production monitoring, alerts, and reporting.

Eliminating paper-based processes.

Implementing an online system to track safety training records and medical testing records.

Production Operations Manager

The Production Operations Manager (OM) is responsible for maintaining overall operational

efficiency of production plants, and maintaining costs within budget. Production OM goals include:

Monitoring and reporting on safety performance for all plants.

Implementing a company-wide safety certfication management system.

Eliminating manual reporting on operational key performance indicators (KPIs).

Corporate Controller

The Corporate Controller is responsible for financial management, the IT department, budgeting,

and treasury.

Corporate Controller goals in clude:

Addressing unbudgeted costs that result from non-compliance issues.

Gathering business performance data worldwide and reconciling all data.

Addressing poor productivity caused by the lack of information sharing

Plant Safety Department Manager

The Plant Safety Department Manager is responsible for managing safety education and medical

testing. Plant Safety Department Manager goals include:

Accompanying government safety inspectors during their plant visits.

Implementing e-mail to notify employees who are due for training and testing.

Implementing alerts to the Human Resources department (HR) when employee are uncertified.

Implementing the daily sorting of spreadsheets to identify which employee are due for training

and testing.

###EndCaseStudy###

You are evaluating an automated safety certification management system for Fabrikam. You

need to identify how Fabrikam will most benefit from the solution. Which financial benefit should

you identify?

Which interviewee should you identify?

###BeginCaseStudy###

Case Study# 2

Corporate Information and Physical Locations.

Fabrikrm,Inc. is a building materials manufacturing company that specializes in producing raw

materials. Fabrikam customers include companies that make products for residential and

commiercial construction projects. Fabrikam has 5,000 employees and earns $600 million in

annual revenues. Fabrikam has plans and offices worldwide.

EXISTING ENVIRONMENT

Existing Business Processes

Fabrikam has the following business processes:

The Plant Safety department is responsible for notifying and scheduling employees for safety

training and medical testing procedures. The department also records and reports on training and

testing procedures for management and government safety regulatory agencies. All emplloyees

are required to pass an annual mine safety training course and various medica certification tests

to continue working. Non-compliant employees cannot work, reducing production enfficiency.

Government safety inpectors perform random onsite inspections and verify that employees are

certified. Each item of non-compliance costs Fabrikam time and lowers employee productivity.

The Plant Safet department hired a full-time Safety Coordinatinator and a temporary employee to

help employees maintain their certifications. They notify employees when their certifications are

about to expire and assist employees to schedule appointments to renew their certifications.

Existing Technology Infrastructure

Fabrikam has the following technologies implemented on the network:

A third-party, Web-based workforce management application

A Microsoft SQL Server-based Enterprise Resource Planning (ERP) system

Microsoft Office Excel used to update safety information by using spreadsheets.

Farbrikam has a Microsoft Enterprise Agreement (EA) that includes Microsoft Software

Assurance (SA). All client computers run either Microsoft Office Standard Edition 2003 or

Microsoft Office 97. The department is underskilled and understaffed.

BUSINESS REQUIREMENTS

Planned Changes

Fabrikam has the following business goals:

Provide role-based access to process, operational, and financial information.

Eliminate paper-based processes, including reporting processes.

Reduce the number of technology platforms that require support.

Problem Statements

Fabrikam has identified the following business problems:

Mine safety compliance issues have shut down production at some plants, creating 60 days of

lost productivity during the past year.

Safety training records are often inaccessible.

Training dates and medical testing results are often outdated.

Safety reports are only available to managers at the end of each month.

Safety performance metrics are shared via e-mail only.

Plant safety training and medical testing data is recorded on paper forms and then entered

manually into a spreadsheet on a Safety Manager’s computer.

Reporting is delayed because safety data is outdated and inaccurate.

Business Goals

Fabrikam has the following business goals:

Reduce costs associated with meeting regulatory compliance requirements:

Eliminate paper-based processes.

Improve access to safety performance reporting.

INTERVIEWEES

Vice President (VP) The VP is the executive responsible for overseeing general business

operations and for maintaining profitability. VP goals include:

Rducing operational cost. Increasing production productivity

Eliminating plant shutdowns caused by non-compliance.

Plant General Manager

The Plant General Manager (GM) is responsible for maintaining plant profitability, operational

efficientcy, production costs, product quality, and employee safety. Plant GM goals include:

Automating production monitoring, alerts, and reporting.

Eliminating paper-based processes.

Implementing an online system to track safety training records and medical testing records.

Production Operations Manager

The Production Operations Manager (OM) is responsible for maintaining overall operational

efficiency of production plants, and maintaining costs within budget. Production OM goals include:

Monitoring and reporting on safety performance for all plants.

Implementing a company-wide safety certfication management system.

Eliminating manual reporting on operational key performance indicators (KPIs).

Corporate Controller

The Corporate Controller is responsible for financial management, the IT department, budgeting,

and treasury.

Corporate Controller goals in clude:

Addressing unbudgeted costs that result from non-compliance issues.

Gathering business performance data worldwide and reconciling all data.

Addressing poor productivity caused by the lack of information sharing

Plant Safety Department Manager

The Plant Safety Department Manager is responsible for managing safety education and medical

testing. Plant Safety Department Manager goals include:

Accompanying government safety inspectors during their plant visits.

Implementing e-mail to notify employees who are due for training and testing.

Implementing alerts to the Human Resources department (HR) when employee are uncertified.

Implementing the daily sorting of spreadsheets to identify which employee are due for training

and testing.

###EndCaseStudy###

You are evaluating a company-wide safety management solution for Fabrikam. You need to

identify which Fabrikam interviewee is responsible for implementing this solution. Which

interviewee should you identify?

Which process should you identify?

###BeginCaseStudy###

Case Study# 2

Corporate Information and Physical Locations.

Fabrikrm,Inc. is a building materials manufacturing company that specializes in producing raw

materials. Fabrikam customers include companies that make products for residential and

commiercial construction projects. Fabrikam has 5,000 employees and earns $600 million in

annual revenues. Fabrikam has plans and offices worldwide.

EXISTING ENVIRONMENT

Existing Business Processes

Fabrikam has the following business processes:

The Plant Safety department is responsible for notifying and scheduling employees for safety

training and medical testing procedures. The department also records and reports on training and

testing procedures for management and government safety regulatory agencies. All emplloyees

are required to pass an annual mine safety training course and various medica certification tests

to continue working. Non-compliant employees cannot work, reducing production enfficiency.

Government safety inpectors perform random onsite inspections and verify that employees are

certified. Each item of non-compliance costs Fabrikam time and lowers employee productivity.

The Plant Safet department hired a full-time Safety Coordinatinator and a temporary employee to

help employees maintain their certifications. They notify employees when their certifications are

about to expire and assist employees to schedule appointments to renew their certifications.

Existing Technology Infrastructure

Fabrikam has the following technologies implemented on the network:

A third-party, Web-based workforce management application

A Microsoft SQL Server-based Enterprise Resource Planning (ERP) system

Microsoft Office Excel used to update safety information by using spreadsheets.

Farbrikam has a Microsoft Enterprise Agreement (EA) that includes Microsoft Software

Assurance (SA). All client computers run either Microsoft Office Standard Edition 2003 or

Microsoft Office 97. The department is underskilled and understaffed.

BUSINESS REQUIREMENTS

Planned Changes

Fabrikam has the following business goals:

Provide role-based access to process, operational, and financial information.

Eliminate paper-based processes, including reporting processes.

Reduce the number of technology platforms that require support.

Problem Statements

Fabrikam has identified the following business problems:

Mine safety compliance issues have shut down production at some plants, creating 60 days of

lost productivity during the past year.

Safety training records are often inaccessible.

Training dates and medical testing results are often outdated.

Safety reports are only available to managers at the end of each month.

Safety performance metrics are shared via e-mail only.

Plant safety training and medical testing data is recorded on paper forms and then entered

manually into a spreadsheet on a Safety Manager’s computer.

Reporting is delayed because safety data is outdated and inaccurate.

Business Goals

Fabrikam has the following business goals:

Reduce costs associated with meeting regulatory compliance requirements:

Eliminate paper-based processes.

Improve access to safety performance reporting.

INTERVIEWEES

Vice President (VP) The VP is the executive responsible for overseeing general business

operations and for maintaining profitability. VP goals include:

Rducing operational cost. Increasing production productivity

Eliminating plant shutdowns caused by non-compliance.

Plant General Manager

The Plant General Manager (GM) is responsible for maintaining plant profitability, operational

efficientcy, production costs, product quality, and employee safety. Plant GM goals include:

Automating production monitoring, alerts, and reporting.

Eliminating paper-based processes.

Implementing an online system to track safety training records and medical testing records.

Production Operations Manager

The Production Operations Manager (OM) is responsible for maintaining overall operational

efficiency of production plants, and maintaining costs within budget. Production OM goals include:

Monitoring and reporting on safety performance for all plants.

Implementing a company-wide safety certfication management system.

Eliminating manual reporting on operational key performance indicators (KPIs).

Corporate Controller

The Corporate Controller is responsible for financial management, the IT department, budgeting,

and treasury.

Corporate Controller goals in clude:

Addressing unbudgeted costs that result from non-compliance issues.

Gathering business performance data worldwide and reconciling all data.

Addressing poor productivity caused by the lack of information sharing

Plant Safety Department Manager

The Plant Safety Department Manager is responsible for managing safety education and medical

testing. Plant Safety Department Manager goals include:

Accompanying government safety inspectors during their plant visits.

Implementing e-mail to notify employees who are due for training and testing.

Implementing alerts to the Human Resources department (HR) when employee are uncertified.

Implementing the daily sorting of spreadsheets to identify which employee are due for training

and testing.

###EndCaseStudy###

You need to identify which business process Fabrikam must improve. Which process should you

identify?

What should you recommend?

###BeginCaseStudy###

Case Study# 2

Corporate Information and Physical Locations.

Fabrikrm,Inc. is a building materials manufacturing company that specializes in producing raw

materials. Fabrikam customers include companies that make products for residential and

commiercial construction projects. Fabrikam has 5,000 employees and earns $600 million in

annual revenues. Fabrikam has plans and offices worldwide.

EXISTING ENVIRONMENT

Existing Business Processes

Fabrikam has the following business processes:

The Plant Safety department is responsible for notifying and scheduling employees for safety

training and medical testing procedures. The department also records and reports on training and

testing procedures for management and government safety regulatory agencies. All emplloyees

are required to pass an annual mine safety training course and various medica certification tests

to continue working. Non-compliant employees cannot work, reducing production enfficiency.

Government safety inpectors perform random onsite inspections and verify that employees are

certified. Each item of non-compliance costs Fabrikam time and lowers employee productivity.

The Plant Safet department hired a full-time Safety Coordinatinator and a temporary employee to

help employees maintain their certifications. They notify employees when their certifications are

about to expire and assist employees to schedule appointments to renew their certifications.

Existing Technology Infrastructure

Fabrikam has the following technologies implemented on the network:

A third-party, Web-based workforce management application

A Microsoft SQL Server-based Enterprise Resource Planning (ERP) system

Microsoft Office Excel used to update safety information by using spreadsheets.

Farbrikam has a Microsoft Enterprise Agreement (EA) that includes Microsoft Software

Assurance (SA). All client computers run either Microsoft Office Standard Edition 2003 or

Microsoft Office 97. The department is underskilled and understaffed.

BUSINESS REQUIREMENTS

Planned Changes

Fabrikam has the following business goals:

Provide role-based access to process, operational, and financial information.

Eliminate paper-based processes, including reporting processes.

Reduce the number of technology platforms that require support.

Problem Statements

Fabrikam has identified the following business problems:

Mine safety compliance issues have shut down production at some plants, creating 60 days of

lost productivity during the past year.

Safety training records are often inaccessible.

Training dates and medical testing results are often outdated.

Safety reports are only available to managers at the end of each month.

Safety performance metrics are shared via e-mail only.

Plant safety training and medical testing data is recorded on paper forms and then entered

manually into a spreadsheet on a Safety Manager’s computer.

Reporting is delayed because safety data is outdated and inaccurate.

Business Goals

Fabrikam has the following business goals:

Reduce costs associated with meeting regulatory compliance requirements:

Eliminate paper-based processes.

Improve access to safety performance reporting.

INTERVIEWEES

Vice President (VP) The VP is the executive responsible for overseeing general business

operations and for maintaining profitability. VP goals include:

Rducing operational cost. Increasing production productivity

Eliminating plant shutdowns caused by non-compliance.

Plant General Manager

The Plant General Manager (GM) is responsible for maintaining plant profitability, operational

efficientcy, production costs, product quality, and employee safety. Plant GM goals include:

Automating production monitoring, alerts, and reporting.

Eliminating paper-based processes.

Implementing an online system to track safety training records and medical testing records.

Production Operations Manager

The Production Operations Manager (OM) is responsible for maintaining overall operational

efficiency of production plants, and maintaining costs within budget. Production OM goals include:

Monitoring and reporting on safety performance for all plants.

Implementing a company-wide safety certfication management system.

Eliminating manual reporting on operational key performance indicators (KPIs).

Corporate Controller

The Corporate Controller is responsible for financial management, the IT department, budgeting,

and treasury.

Corporate Controller goals in clude:

Addressing unbudgeted costs that result from non-compliance issues.

Gathering business performance data worldwide and reconciling all data.

Addressing poor productivity caused by the lack of information sharing

Plant Safety Department Manager

The Plant Safety Department Manager is responsible for managing safety education and medical

testing. Plant Safety Department Manager goals include:

Accompanying government safety inspectors during their plant visits.

Implementing e-mail to notify employees who are due for training and testing.

Implementing alerts to the Human Resources department (HR) when employee are uncertified.

Implementing the daily sorting of spreadsheets to identify which employee are due for training

and testing.

###EndCaseStudy###

You are evaluating a safety certification management system for Fabrikam. You need to

recommend a solution to resolve the Fabrikam staffing gap. The solution must support the

companys future state. What should you recommend?

Which adoption risk should you identify?

###BeginCaseStudy###

Case Study# 2

Corporate Information and Physical Locations.

Fabrikrm,Inc. is a building materials manufacturing company that specializes in producing raw

materials. Fabrikam customers include companies that make products for residential and

commiercial construction projects. Fabrikam has 5,000 employees and earns $600 million in

annual revenues. Fabrikam has plans and offices worldwide.

EXISTING ENVIRONMENT

Existing Business Processes

Fabrikam has the following business processes:

The Plant Safety department is responsible for notifying and scheduling employees for safety

training and medical testing procedures. The department also records and reports on training and

testing procedures for management and government safety regulatory agencies. All emplloyees

are required to pass an annual mine safety training course and various medica certification tests

to continue working. Non-compliant employees cannot work, reducing production enfficiency.

Government safety inpectors perform random onsite inspections and verify that employees are

certified. Each item of non-compliance costs Fabrikam time and lowers employee productivity.

The Plant Safet department hired a full-time Safety Coordinatinator and a temporary employee to

help employees maintain their certifications. They notify employees when their certifications are

about to expire and assist employees to schedule appointments to renew their certifications.

Existing Technology Infrastructure

Fabrikam has the following technologies implemented on the network:

A third-party, Web-based workforce management application

A Microsoft SQL Server-based Enterprise Resource Planning (ERP) system

Microsoft Office Excel used to update safety information by using spreadsheets.

Farbrikam has a Microsoft Enterprise Agreement (EA) that includes Microsoft Software

Assurance (SA). All client computers run either Microsoft Office Standard Edition 2003 or

Microsoft Office 97. The department is underskilled and understaffed.

BUSINESS REQUIREMENTS

Planned Changes

Fabrikam has the following business goals:

Provide role-based access to process, operational, and financial information.

Eliminate paper-based processes, including reporting processes.

Reduce the number of technology platforms that require support.

Problem Statements

Fabrikam has identified the following business problems:

Mine safety compliance issues have shut down production at some plants, creating 60 days of

lost productivity during the past year.

Safety training records are often inaccessible.

Training dates and medical testing results are often outdated.

Safety reports are only available to managers at the end of each month.

Safety performance metrics are shared via e-mail only.

Plant safety training and medical testing data is recorded on paper forms and then entered

manually into a spreadsheet on a Safety Manager’s computer.

Reporting is delayed because safety data is outdated and inaccurate.

Business Goals

Fabrikam has the following business goals:

Reduce costs associated with meeting regulatory compliance requirements:

Eliminate paper-based processes.

Improve access to safety performance reporting.

INTERVIEWEES

Vice President (VP) The VP is the executive responsible for overseeing general business

operations and for maintaining profitability. VP goals include:

Rducing operational cost. Increasing production productivity

Eliminating plant shutdowns caused by non-compliance.

Plant General Manager

The Plant General Manager (GM) is responsible for maintaining plant profitability, operational

efficientcy, production costs, product quality, and employee safety. Plant GM goals include:

Automating production monitoring, alerts, and reporting.

Eliminating paper-based processes.

Implementing an online system to track safety training records and medical testing records.

Production Operations Manager

The Production Operations Manager (OM) is responsible for maintaining overall operational

efficiency of production plants, and maintaining costs within budget. Production OM goals include:

Monitoring and reporting on safety performance for all plants.

Implementing a company-wide safety certfication management system.

Eliminating manual reporting on operational key performance indicators (KPIs).

Corporate Controller

The Corporate Controller is responsible for financial management, the IT department, budgeting,

and treasury.

Corporate Controller goals in clude:

Addressing unbudgeted costs that result from non-compliance issues.

Gathering business performance data worldwide and reconciling all data.

Addressing poor productivity caused by the lack of information sharing

Plant Safety Department Manager

The Plant Safety Department Manager is responsible for managing safety education and medical

testing. Plant Safety Department Manager goals include:

Accompanying government safety inspectors during their plant visits.

Implementing e-mail to notify employees who are due for training and testing.

Implementing alerts to the Human Resources department (HR) when employee are uncertified.

Implementing the daily sorting of spreadsheets to identify which employee are due for training

and testing.

###EndCaseStudy###

You are evaluating an automated safety certification management system for Fabrikam. You

need to identify the primary adoption risk inherent in this solution. Which adoption risk should you

identify?

What should you recommend?

###BeginCaseStudy###

Case Study# 2

Corporate Information and Physical Locations.

Fabrikrm,Inc. is a building materials manufacturing company that specializes in producing raw

materials. Fabrikam customers include companies that make products for residential and

commiercial construction projects. Fabrikam has 5,000 employees and earns $600 million in

annual revenues. Fabrikam has plans and offices worldwide.

EXISTING ENVIRONMENT

Existing Business Processes

Fabrikam has the following business processes:

The Plant Safety department is responsible for notifying and scheduling employees for safety

training and medical testing procedures. The department also records and reports on training and

testing procedures for management and government safety regulatory agencies. All emplloyees

are required to pass an annual mine safety training course and various medica certification tests

to continue working. Non-compliant employees cannot work, reducing production enfficiency.

Government safety inpectors perform random onsite inspections and verify that employees are

certified. Each item of non-compliance costs Fabrikam time and lowers employee productivity.

The Plant Safet department hired a full-time Safety Coordinatinator and a temporary employee to

help employees maintain their certifications. They notify employees when their certifications are

about to expire and assist employees to schedule appointments to renew their certifications.

Existing Technology Infrastructure

Fabrikam has the following technologies implemented on the network:

A third-party, Web-based workforce management application

A Microsoft SQL Server-based Enterprise Resource Planning (ERP) system

Microsoft Office Excel used to update safety information by using spreadsheets.

Farbrikam has a Microsoft Enterprise Agreement (EA) that includes Microsoft Software

Assurance (SA). All client computers run either Microsoft Office Standard Edition 2003 or

Microsoft Office 97. The department is underskilled and understaffed.

BUSINESS REQUIREMENTS

Planned Changes

Fabrikam has the following business goals:

Provide role-based access to process, operational, and financial information.

Eliminate paper-based processes, including reporting processes.

Reduce the number of technology platforms that require support.

Problem Statements

Fabrikam has identified the following business problems:

Mine safety compliance issues have shut down production at some plants, creating 60 days of

lost productivity during the past year.

Safety training records are often inaccessible.

Training dates and medical testing results are often outdated.

Safety reports are only available to managers at the end of each month.

Safety performance metrics are shared via e-mail only.

Plant safety training and medical testing data is recorded on paper forms and then entered

manually into a spreadsheet on a Safety Manager’s computer.

Reporting is delayed because safety data is outdated and inaccurate.

Business Goals

Fabrikam has the following business goals:

Reduce costs associated with meeting regulatory compliance requirements:

Eliminate paper-based processes.

Improve access to safety performance reporting.

INTERVIEWEES

Vice President (VP) The VP is the executive responsible for overseeing general business

operations and for maintaining profitability. VP goals include:

Rducing operational cost. Increasing production productivity

Eliminating plant shutdowns caused by non-compliance.

Plant General Manager

The Plant General Manager (GM) is responsible for maintaining plant profitability, operational

efficientcy, production costs, product quality, and employee safety. Plant GM goals include:

Automating production monitoring, alerts, and reporting.

Eliminating paper-based processes.

Implementing an online system to track safety training records and medical testing records.

Production Operations Manager

The Production Operations Manager (OM) is responsible for maintaining overall operational

efficiency of production plants, and maintaining costs within budget. Production OM goals include:

Monitoring and reporting on safety performance for all plants.

Implementing a company-wide safety certfication management system.

Eliminating manual reporting on operational key performance indicators (KPIs).

Corporate Controller

The Corporate Controller is responsible for financial management, the IT department, budgeting,

and treasury.

Corporate Controller goals in clude:

Addressing unbudgeted costs that result from non-compliance issues.

Gathering business performance data worldwide and reconciling all data.

Addressing poor productivity caused by the lack of information sharing

Plant Safety Department Manager

The Plant Safety Department Manager is responsible for managing safety education and medical

testing. Plant Safety Department Manager goals include:

Accompanying government safety inspectors during their plant visits.

Implementing e-mail to notify employees who are due for training and testing.

Implementing alerts to the Human Resources department (HR) when employee are uncertified.

Implementing the daily sorting of spreadsheets to identify which employee are due for training

and testing.

###EndCaseStudy###

You are evaluating an Office System solution for the Fabrikam employee certification process.

You need to recommend a solution to improve the process. What should you recommend?

You need to create a current state business process diagram

###BeginCaseStudy###

Case Study# 2

Corporate Information and Physical Locations.

Fabrikrm,Inc. is a building materials manufacturing company that specializes in producing raw

materials. Fabrikam customers include companies that make products for residential and

commiercial construction projects. Fabrikam has 5,000 employees and earns $600 million in

annual revenues. Fabrikam has plans and offices worldwide.

EXISTING ENVIRONMENT

Existing Business Processes

Fabrikam has the following business processes:

The Plant Safety department is responsible for notifying and scheduling employees for safety

training and medical testing procedures. The department also records and reports on training and

testing procedures for management and government safety regulatory agencies. All emplloyees

are required to pass an annual mine safety training course and various medica certification tests

to continue working. Non-compliant employees cannot work, reducing production enfficiency.

Government safety inpectors perform random onsite inspections and verify that employees are

certified. Each item of non-compliance costs Fabrikam time and lowers employee productivity.

The Plant Safet department hired a full-time Safety Coordinatinator and a temporary employee to

help employees maintain their certifications. They notify employees when their certifications are

about to expire and assist employees to schedule appointments to renew their certifications.

Existing Technology Infrastructure

Fabrikam has the following technologies implemented on the network:

A third-party, Web-based workforce management application

A Microsoft SQL Server-based Enterprise Resource Planning (ERP) system

Microsoft Office Excel used to update safety information by using spreadsheets.

Farbrikam has a Microsoft Enterprise Agreement (EA) that includes Microsoft Software

Assurance (SA). All client computers run either Microsoft Office Standard Edition 2003 or

Microsoft Office 97. The department is underskilled and understaffed.

BUSINESS REQUIREMENTS

Planned Changes

Fabrikam has the following business goals:

Provide role-based access to process, operational, and financial information.

Eliminate paper-based processes, including reporting processes.

Reduce the number of technology platforms that require support.

Problem Statements

Fabrikam has identified the following business problems:

Mine safety compliance issues have shut down production at some plants, creating 60 days of

lost productivity during the past year.

Safety training records are often inaccessible.

Training dates and medical testing results are often outdated.

Safety reports are only available to managers at the end of each month.

Safety performance metrics are shared via e-mail only.

Plant safety training and medical testing data is recorded on paper forms and then entered

manually into a spreadsheet on a Safety Manager’s computer.

Reporting is delayed because safety data is outdated and inaccurate.

Business Goals

Fabrikam has the following business goals:

Reduce costs associated with meeting regulatory compliance requirements:

Eliminate paper-based processes.

Improve access to safety performance reporting.

INTERVIEWEES

Vice President (VP) The VP is the executive responsible for overseeing general business

operations and for maintaining profitability. VP goals include:

Rducing operational cost. Increasing production productivity

Eliminating plant shutdowns caused by non-compliance.

Plant General Manager

The Plant General Manager (GM) is responsible for maintaining plant profitability, operational

efficientcy, production costs, product quality, and employee safety. Plant GM goals include:

Automating production monitoring, alerts, and reporting.

Eliminating paper-based processes.

Implementing an online system to track safety training records and medical testing records.

Production Operations Manager

The Production Operations Manager (OM) is responsible for maintaining overall operational

efficiency of production plants, and maintaining costs within budget. Production OM goals include:

Monitoring and reporting on safety performance for all plants.

Implementing a company-wide safety certfication management system.

Eliminating manual reporting on operational key performance indicators (KPIs).

Corporate Controller

The Corporate Controller is responsible for financial management, the IT department, budgeting,

and treasury.

Corporate Controller goals in clude:

Addressing unbudgeted costs that result from non-compliance issues.

Gathering business performance data worldwide and reconciling all data.

Addressing poor productivity caused by the lack of information sharing

Plant Safety Department Manager

The Plant Safety Department Manager is responsible for managing safety education and medical

testing. Plant Safety Department Manager goals include:

Accompanying government safety inspectors during their plant visits.

Implementing e-mail to notify employees who are due for training and testing.

Implementing alerts to the Human Resources department (HR) when employee are uncertified.

Implementing the daily sorting of spreadsheets to identify which employee are due for training

and testing.

###EndCaseStudy###

You need to create a current state business process diagram. What should you do to gather the

required information?

What are the annual total savings?

###BeginCaseStudy###

Case Study# 2

Corporate Information and Physical Locations.

Fabrikrm,Inc. is a building materials manufacturing company that specializes in producing raw

materials. Fabrikam customers include companies that make products for residential and

commiercial construction projects. Fabrikam has 5,000 employees and earns $600 million in

annual revenues. Fabrikam has plans and offices worldwide.

EXISTING ENVIRONMENT

Existing Business Processes

Fabrikam has the following business processes:

The Plant Safety department is responsible for notifying and scheduling employees for safety

training and medical testing procedures. The department also records and reports on training and

testing procedures for management and government safety regulatory agencies. All emplloyees

are required to pass an annual mine safety training course and various medica certification tests

to continue working. Non-compliant employees cannot work, reducing production enfficiency.

Government safety inpectors perform random onsite inspections and verify that employees are

certified. Each item of non-compliance costs Fabrikam time and lowers employee productivity.

The Plant Safet department hired a full-time Safety Coordinatinator and a temporary employee to

help employees maintain their certifications. They notify employees when their certifications are

about to expire and assist employees to schedule appointments to renew their certifications.

Existing Technology Infrastructure

Fabrikam has the following technologies implemented on the network:

A third-party, Web-based workforce management application

A Microsoft SQL Server-based Enterprise Resource Planning (ERP) system

Microsoft Office Excel used to update safety information by using spreadsheets.

Farbrikam has a Microsoft Enterprise Agreement (EA) that includes Microsoft Software

Assurance (SA). All client computers run either Microsoft Office Standard Edition 2003 or

Microsoft Office 97. The department is underskilled and understaffed.

BUSINESS REQUIREMENTS

Planned Changes

Fabrikam has the following business goals:

Provide role-based access to process, operational, and financial information.

Eliminate paper-based processes, including reporting processes.

Reduce the number of technology platforms that require support.

Problem Statements

Fabrikam has identified the following business problems:

Mine safety compliance issues have shut down production at some plants, creating 60 days of

lost productivity during the past year.

Safety training records are often inaccessible.

Training dates and medical testing results are often outdated.

Safety reports are only available to managers at the end of each month.

Safety performance metrics are shared via e-mail only.

Plant safety training and medical testing data is recorded on paper forms and then entered

manually into a spreadsheet on a Safety Manager’s computer.

Reporting is delayed because safety data is outdated and inaccurate.

Business Goals

Fabrikam has the following business goals:

Reduce costs associated with meeting regulatory compliance requirements:

Eliminate paper-based processes.

Improve access to safety performance reporting.

INTERVIEWEES

Vice President (VP) The VP is the executive responsible for overseeing general business

operations and for maintaining profitability. VP goals include:

Rducing operational cost. Increasing production productivity

Eliminating plant shutdowns caused by non-compliance.

Plant General Manager

The Plant General Manager (GM) is responsible for maintaining plant profitability, operational

efficientcy, production costs, product quality, and employee safety. Plant GM goals include:

Automating production monitoring, alerts, and reporting.

Eliminating paper-based processes.

Implementing an online system to track safety training records and medical testing records.

Production Operations Manager

The Production Operations Manager (OM) is responsible for maintaining overall operational

efficiency of production plants, and maintaining costs within budget. Production OM goals include:

Monitoring and reporting on safety performance for all plants.

Implementing a company-wide safety certfication management system.

Eliminating manual reporting on operational key performance indicators (KPIs).

Corporate Controller

The Corporate Controller is responsible for financial management, the IT department, budgeting,

and treasury.

Corporate Controller goals in clude:

Addressing unbudgeted costs that result from non-compliance issues.

Gathering business performance data worldwide and reconciling all data.

Addressing poor productivity caused by the lack of information sharing

Plant Safety Department Manager

The Plant Safety Department Manager is responsible for managing safety education and medical

testing. Plant Safety Department Manager goals include:

Accompanying government safety inspectors during their plant visits.

Implementing e-mail to notify employees who are due for training and testing.

Implementing alerts to the Human Resources department (HR) when employee are uncertified.

Implementing the daily sorting of spreadsheets to identify which employee are due for training

and testing.

###EndCaseStudy###

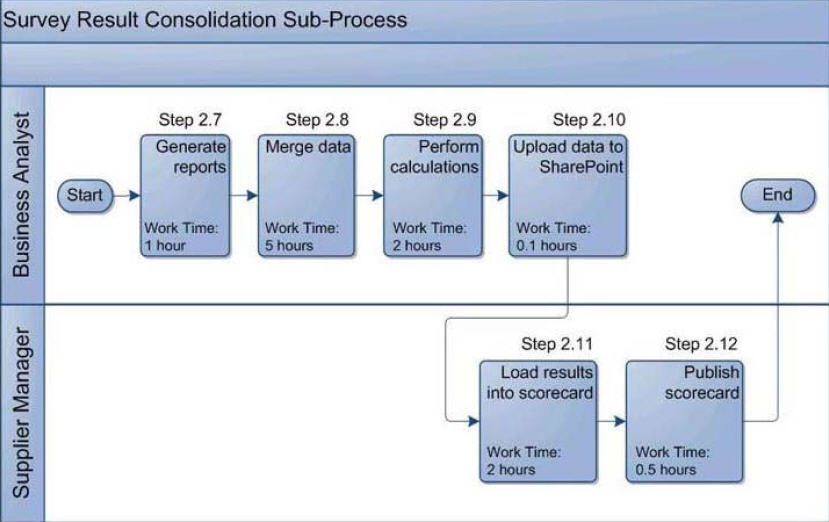

A portion of the current state business process for Woodgrove Bank is shown in the following

exhibit. (Click the Exhibit button.) This portion of the business process is repeated every quarter

for all 40 suppliers that the ESM group manages directly and is completed by one business

manager and one supplier manager. You need to identify the total labor costs the bank would

save by removing lines 2.8 and 2.11 from the process. What are the annual total savings?